Flowmeters ACS

Our quote will always be lower than the manufacturer's price. Please send us the full part number of a device to get a quick response.

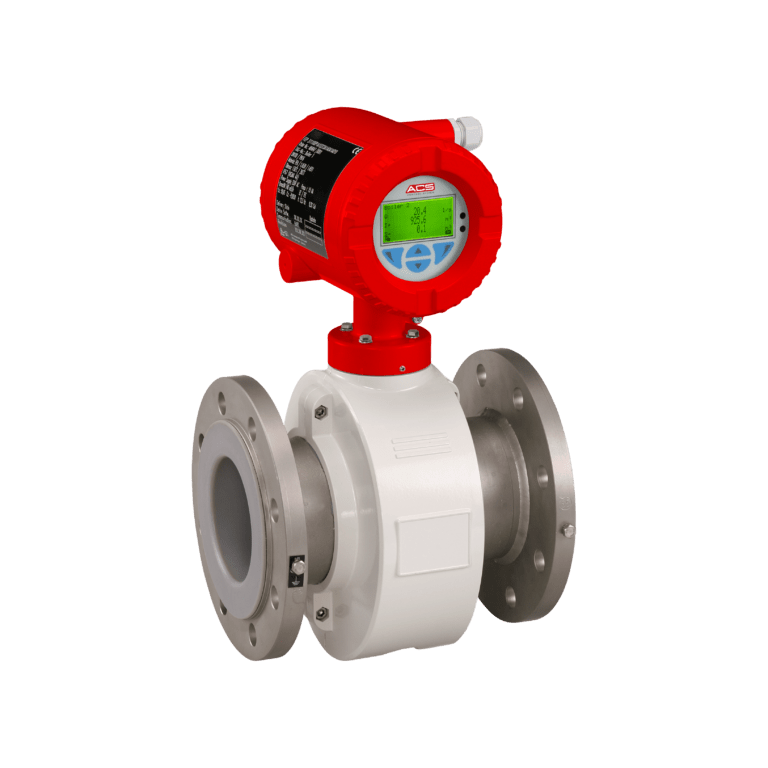

Description A fast and easy change of the factory preset parameter allows the operation friendly display and the sensor keys – without opening the housing. The “Easy-Up” function guides the unpracticed user step by step fast and safe through the configuration. The permissible range of the respective parameter is indicated in the display and unpermitted inputs are rejected. The softkey functionality supports operator kindness and makes the handling easy and simple – like those of a modern mobile phone. Function The Flowcont F630 is featured especially by his backlight illuminated display. Many features can be set by the user:

In the multiplex mode different display settings can be preconfigurated, that can be activated in succession. The “SensorMemory”, that is integrated in the sensor, makes the control of the assignment of measuring sensor and measuring transmitter unnecessary. After power on the auxiliary power the sensor data and the measuring place specific parameter will be loaded automatically. Thus, errors will be eliminated, the inauguration goes faster and safer and avoids problems. Diagnosis functions monitors the functionability of the Flowcont F630 and the engineering of the process. The limit values of the diagnosis parameter can be set in the operation field. At exceeding this limit values an alert occurs. For further analysis the diagnosis data can be read out by a modern infrared interface. This allows a higher productivity and avoids downtimes. The state messages are classified corresponding to the requirements of NAMUR NE107. |

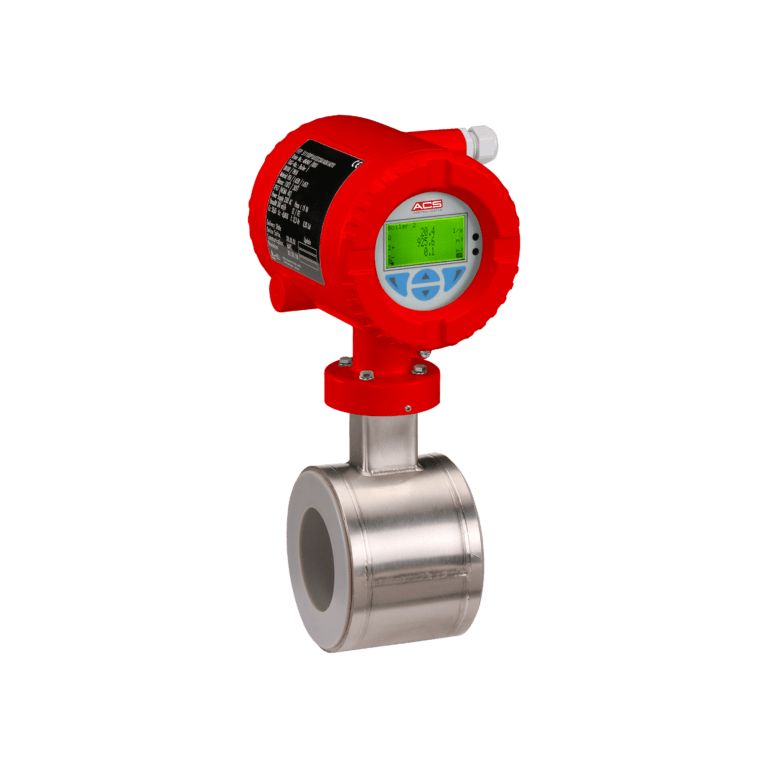

Description A fast and easy change of the factory preset parameter allows the operation friendly display and the sensor keys – without opening the housing. The “Easy-Up” function guides the unpracticed user step by step fast and safe through the configuration. Function the Flowcont L630 is featured especially by his backlight illuminated display. Many features can be set by the user:

In the multiplex mode different display settings can be preconfigurated, that can be activated in succession. The “SensorMemory”, that is integrated in the sensor, makes the control of the assignment of measuring sensor and measuring transmitter unnecessary. After power on the auxiliary power the sensor data and the measuring place specific parameter will be loaded automatically. Thus, errors will be eliminated, the inauguration goes faster and safer and avoids problems. Diagnosis functions monitors the functionability of the Flowcont L630 and the engineering of the process. The limit values of the diagnosis parameter can be set in the operation field. At exceeding this limit values an alert occurs. For further analysis the diagnosis data can be read out by a modern infrared interface. This allows a higher productivity and avoids downtimes. The state messages are classified corresponding to the requirements of NAMUR NE 107. |

Description The Flowcont Magsmall is the economical magmeter for many applications in secondary circuits with conductive liquids in all industries. End customers, skid builders, equipment manufacturers and system integrators value the space-saving Magsmall for its flexible installation capabilities. Additionally, its future-oriented, intuitive operation via SmartBlue app on every Bluetooth®-enabled smartphone or tablet ensures fast, secure and simple commissioning. |

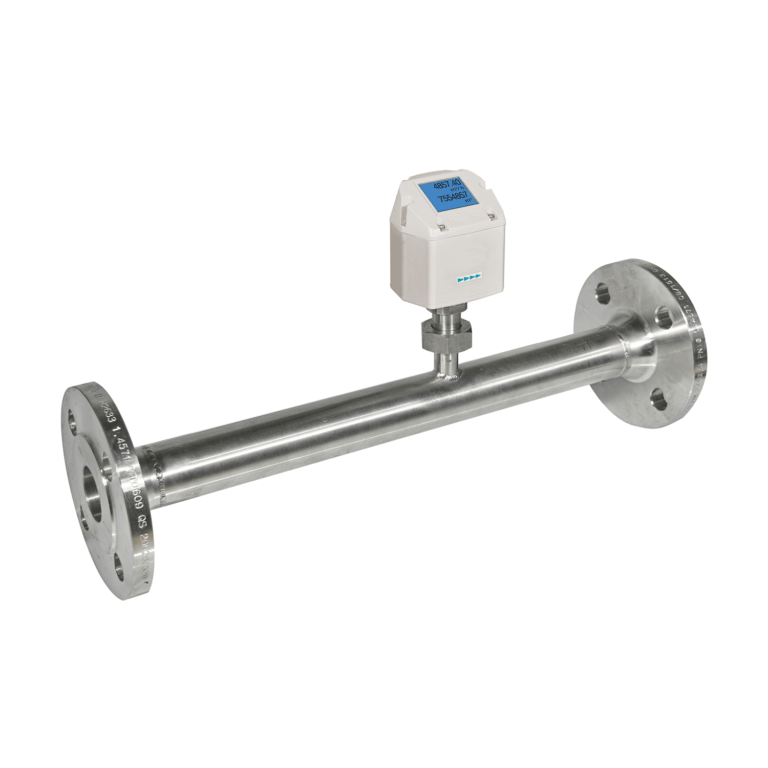

Description The affordable consumption counter Flowgas TMS 300 works according to the proven calorimetric measuring principle. A heated sensor is cooled by the gas flowing around him. The flow-dependent cooling is utilized as a measuring scale while the degree of cooling is directly dependent on the passing air or gas mass. An additional pressure and temperature compensation is therefore not necessary. |

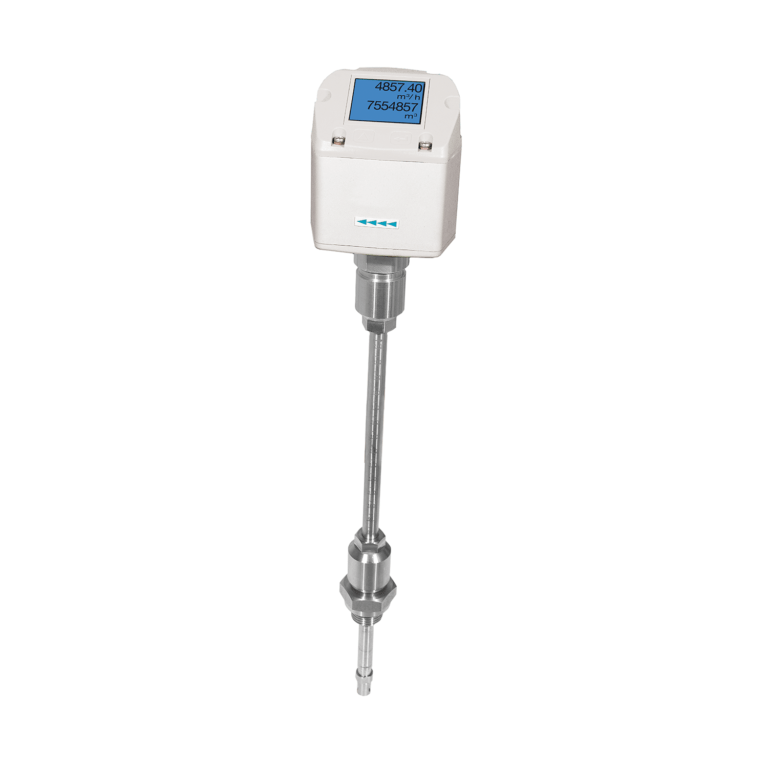

Description The affordable consumption counter Flowgas TMS 500 works according to the proven calorimetric measuring principle. A heated sensor is cooled by the gas flowing around him. The flow-dependent cooling is utilized as a measuring scale while the degree of cooling is directly dependent on the passing air or gas mass. An additional pressure and temperature compensation is therefore not necessary. For larger pipe diameters from DN 50 to DN 300 the consumption sensors TMS 500 are available. In addition to pressure air, other gases can be measured e.g. Nitrogen, oxygen, CO2. The installation of the Flowgas TMS 500 via a standard G 1/2 “ball valve under pressure. The retaining ring prevents the probe is thrown out uncontrollably during installation and removal by the operating pressure. For installation in different pipe diameters the TMS 500 can be associated with different probe lengths. The exact positioning of the sensor in the center of the pipe is possible via an engraved depth scale. |

Description The Fluxicont FS4 is an electronic flow resp. temperature switch for monitoring, control as well as continuous measurement of flow and temperatures in liquids. Due to the device construction with flow velocities from 3cm/s to 300cm/s , process temperatures from –20°C to +110°C, process pressures up to 40bar, process material stainless steel V4A as well as the availability of industrial standard process connections like thread ISO 228-1 thread ANSI NPT – on request and thread ISO 225-1 M18x1,5 for adapter – on request the device is especially suitable for the use for monitoring cooling water circulation systems of pumps, turbines, compressors and heat exchangers, for monitoring pump functionality, for dry run protection for pumps, for leak monitoring in process lines, monitoring lubrication systems and filter monitoring in the beverage industry. The flow switch is suitable for demanding measuring requirements. Due to its high accuracy and the high flexibility of configuration, the Fluxicont FS4 can be suited a wide variety of applications. The robust design and the high-quality workmanship turns the device into a very high quality product, which even the most adverse environmental conditions cannot affect, whether the lowest temperatures when used outdoors, extreme shock and vibration or aggressive media. A captive laser marking of the type label ensures the identifiability throughout the entire lifetime of the device. Obviously is the optional marking of a measurement point designation resp. TAG, a customer label or of a neutral type label, of course also per laser marking. A LABS-free resp. silicone-free version, a factory calibration with calibration certificate and a customer specific configuration resp. preset is also optionally available like a material test certificate EN10204 3.1 or factory certifications for drink water resp. food suitability. Customer specific special versions can be realized on request, e.g. software adaption (menu navigation, special functions, etc.), changed terminal assignment resp. connector orientation, design adaption of the user surface and special designs for the process connection. |

Description Fluxicont FU4SK suitable for general applications in

Fluxicont FU4LK suitable for general applications in

The device is an electronic flow resp. temperature switch for monitoring, control and continuous measurement of flow and temperatures in liquids. A high variety of versions of process connections and electronic types allows the use for a wide range of applications, also for demanding measuring requirements. The process connection of the FU4LK with metallic sealing has been specifically designed for the hygienic, dead-space and elastomer-free process adaption. Due to its high accuracy and the digital adjustability by RS485 Modbus®-RTU or IO-Link® the device can be suited to a wide variety of applications. The robust design and the high-quality workmanship turns the device into a very high quality product, which even the most adverse environmental conditions cannot affect, whether the lowest temperatures when used outdoors, extreme shock and vibration stress or aggressive media. A captive laser marking of the type label ensures the identifiability throughout the entire lifetime of the device. Obviously is the optional marking of a measurement point designation resp. TAG, a customer label or of a neutral type label, of course also per laser marking. A LABS- resp. silicone-free version, a factory calibration with calibration certificate and a customer specific configuration resp. preset is also optionally available like a material test certificate EN10204 3.1 or a factory certifications for drink water resp. food suitability. Customer specific special versions can be realized short-term on request, e.g. special designs for the process connection or other process materials. |

Description Flowcont UN

|