Encoders special model Baumer

The company Baumer is an international business with a passion for sensor technology, encoders, measuring instruments and components for automated image processing. Through a very strong local presence in 39 subsidiaries and 19 countries, Baumer is able to be close to the customers. The outstanding Baumer quality of the vast portfolio of sensors and instruments keeps the company on the road of success in tough international competition. Various expert juries awarded Baumer with national and international prizes for innovation, design and quality as a token for quality and pioneering spirit.

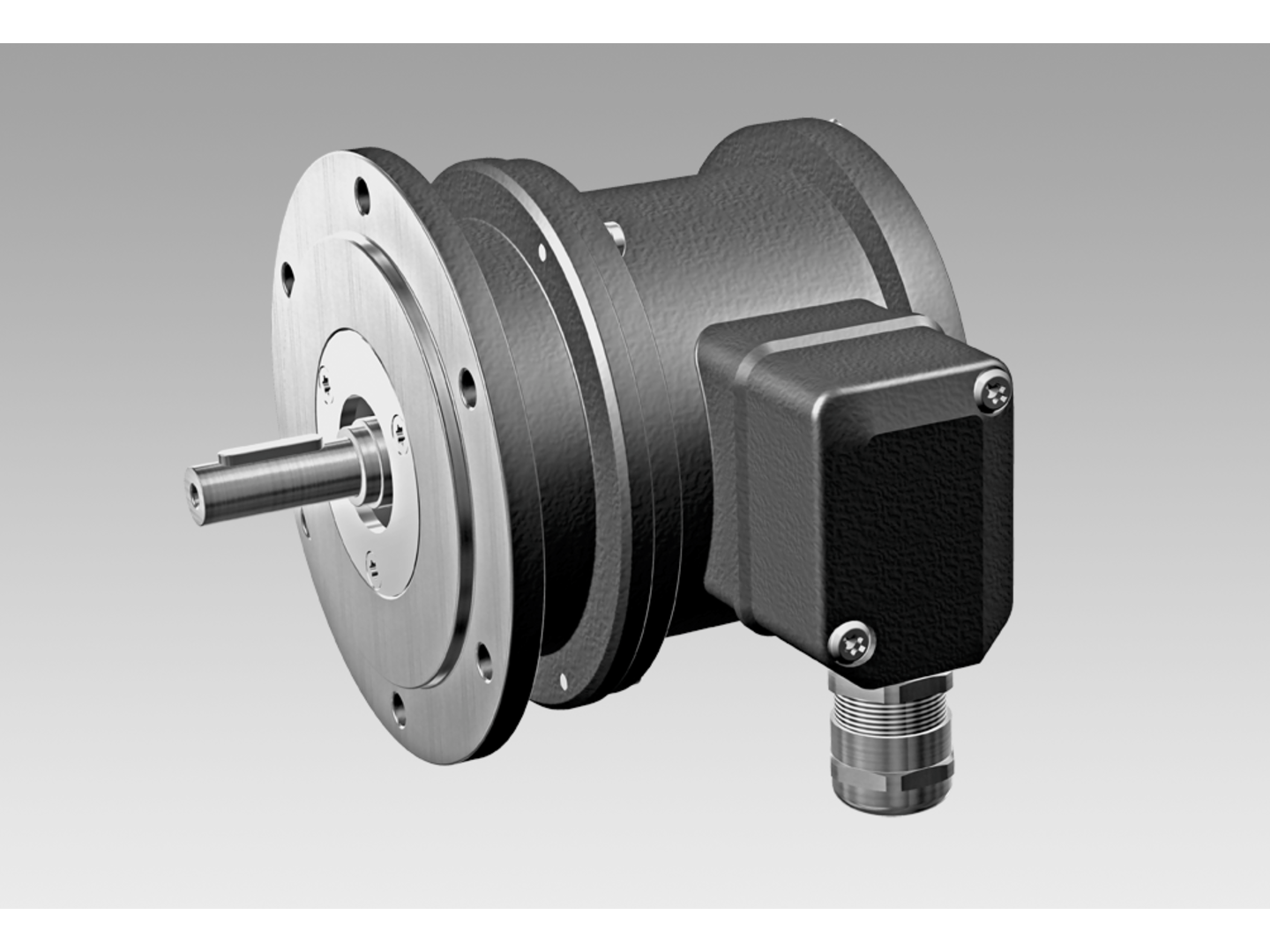

Cable-pull (Wire draw) encoders are the easiest and most reliable options for linear position measurement and positioning. They measure over the entire measuring range in an almost linear manner, and are used for measuring lengths of up to 50 m. The cable pulls are specially designed for industrial applications and are therefore particularly high-quality and durable. Cable-pull encoders are suitable for integrated or subsequent installation, and are perfectly suited for series production by OEMs. Wire draw encoders consist of a wire draw mechanism and an encoder. The rotation of the drum, which is proportional to the length being measured, is recorded and output by an encoder. This facilitates positioning on linear measuring paths. SICK's wire draw encoders support a large selection of interfaces and facilitate easy system integration for applications in challenging industrial settings. Different performance classes make it possible to select the ideal device for the application at hand.

Manufactured part numbers open, use the search ctrl + F

|

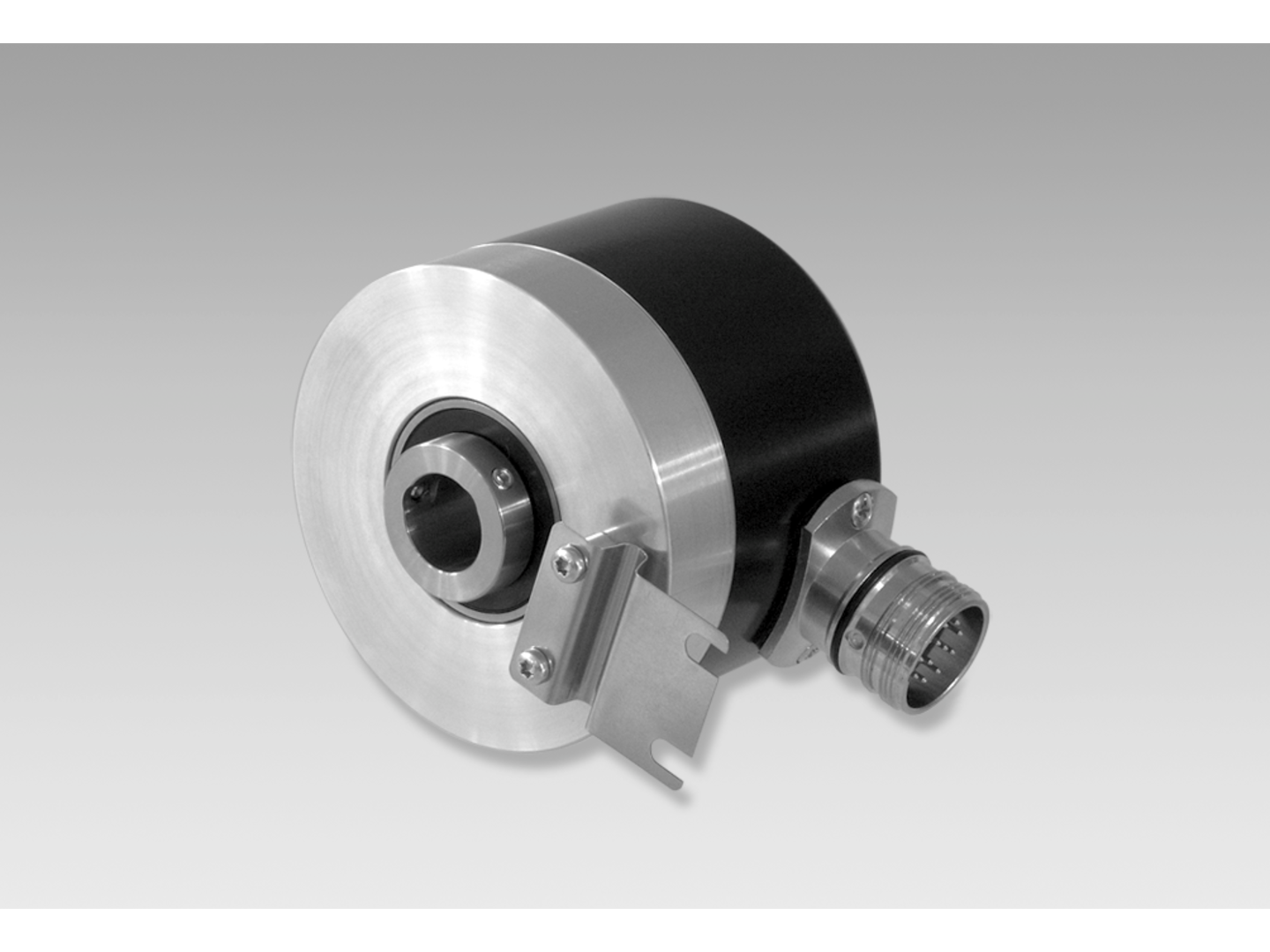

Bearingless encoders. In bearingless encoders the rotor is completely free to move relative to the stator – if bearings are involved they are typically already present in the host system. The eradication of bearings from the encoder results in lower start-up turning torques, no service or maintenance requirements, greater reliability due to reduction in parts count, eradication of seals and baffles, direct coupling of rotor and stator to host equipment, no heat generation from friction at high speeds.

|

Motor earthing unit ATEX/IECEx - EExME 12. Ex-approved by ATEX II 2 G Ex db IIC T4/T5 Gb (gas) and IEC Ex db IIC T4/T5 Gb (gas). EG design test certifcate TÜV NORD CERT No. TÜV 02 ATEX 1920 X IECEx TUN 11.0036X. Leakage of parasetical shaft currents. Hollow shaft ø20...42 mm.

|

Electronic speed switch. Electronic speed monitoring. Circuit breaker with one selectable threshold speed. Relay output with isolated changeover contact.

|

Resolvers RTD series with a solid shaft ø6 mm with synchro flange. Robust resolver with solid shaft ø6 mm. Rotation speed max. 10000 rpm. Centering alignment ø50 mm. Mounting hole circle ø68 mm. Wide operating temperature range. Flange connector radial.

|

Magnetic angle sensors. Current output. Cable PUR 3 x 0.25, 2 m. Temperature -40 … 85 °C, IP67.

|

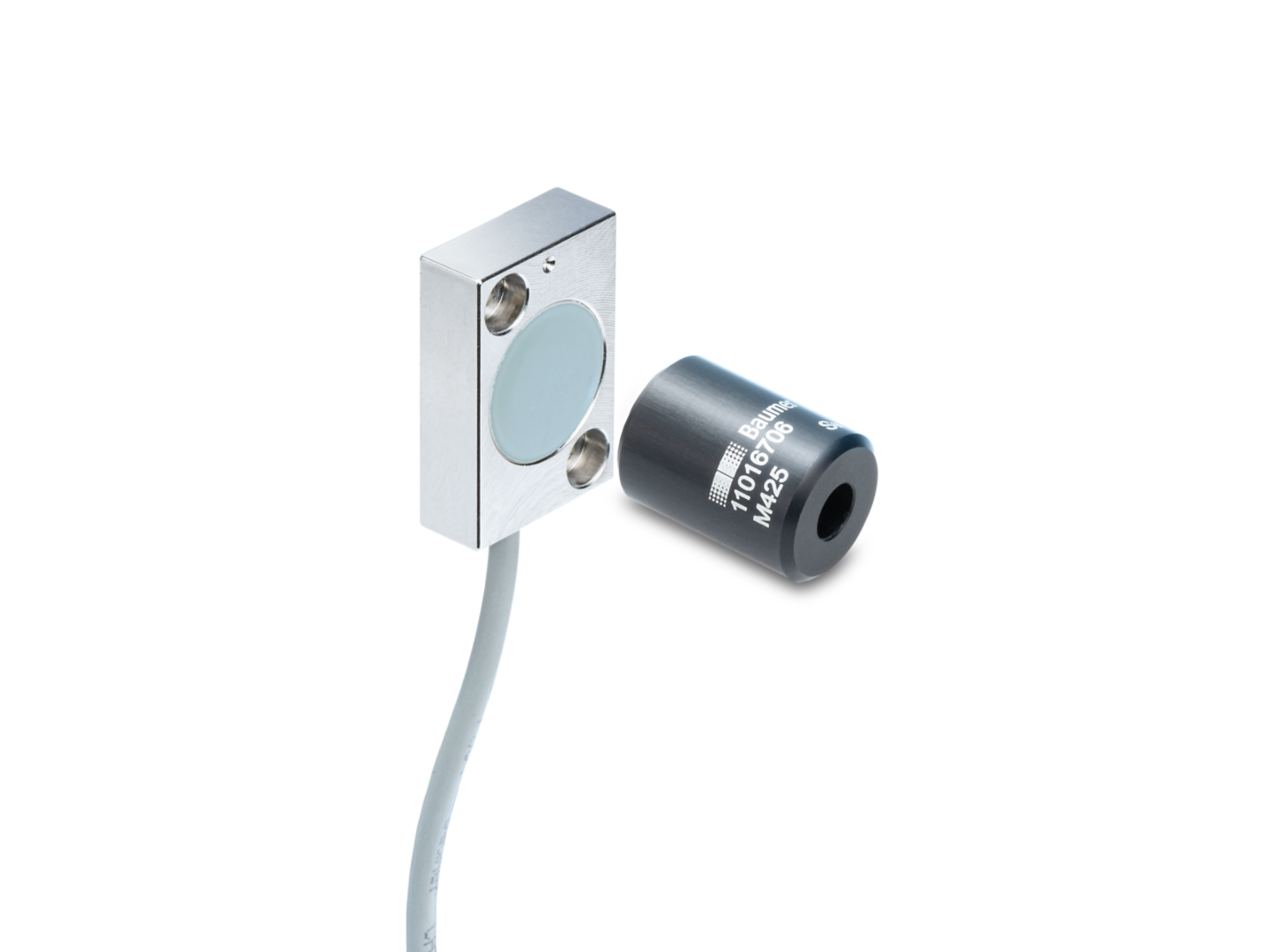

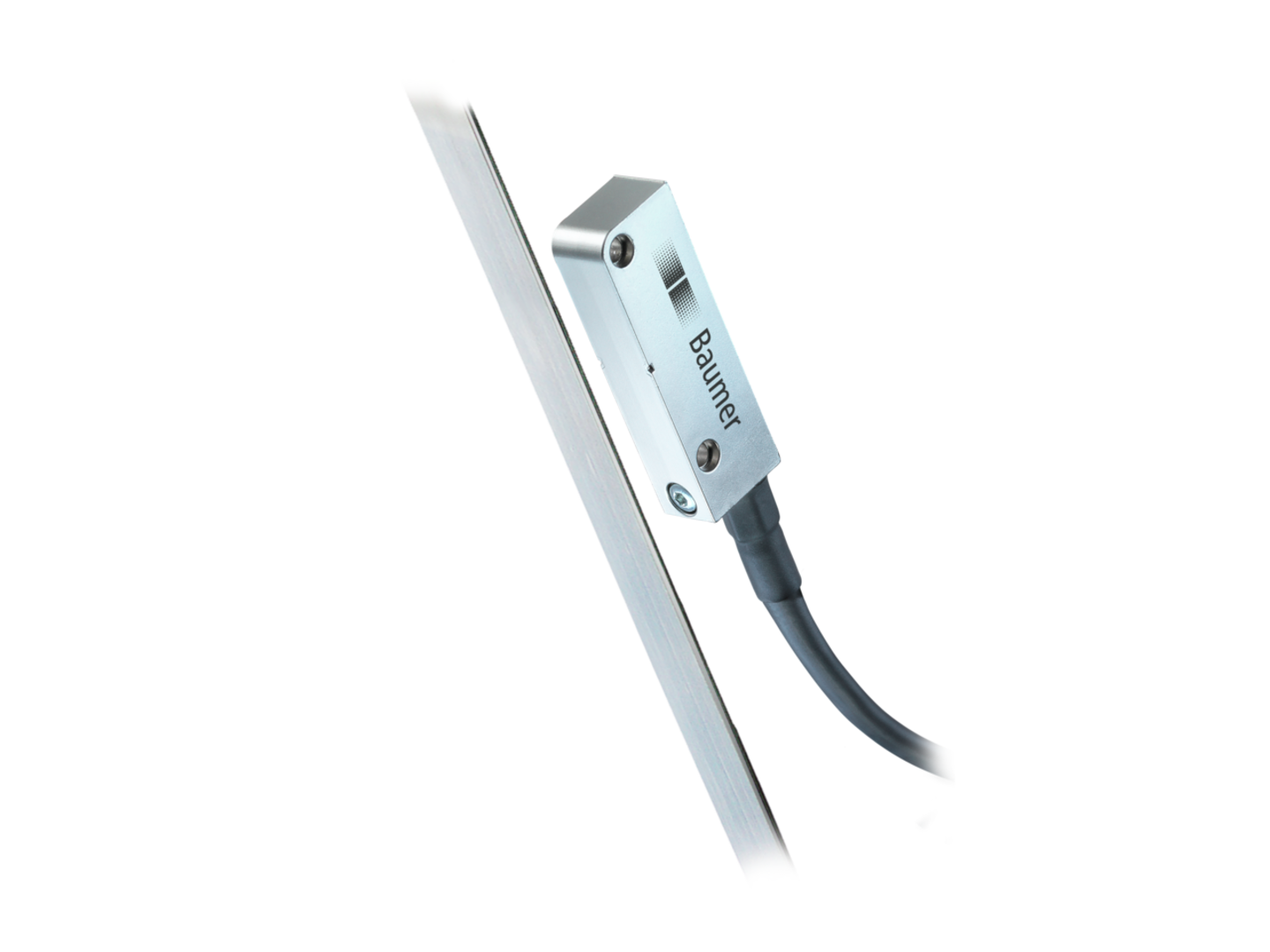

Linear encoders without bearings incremental MIL10. System for linear motion feedback. Sensor head with magnetic tape. Robust magnetic sensing method. Output signals A 90° B with index signal. Output circuits: HTL/push-pull and TTL/RS422. Resolution up to 5 µm (4-times evaluation). Non-contact, wear-free sensing system. High resistance to dirt and vibrations. Manufactured part numbers open, use the search ctrl + F

|